7 Warning Signs Your Dock Equipment Is About to Fail

Loading dock equipment is the lifeblood of your commercial business, and proper maintenance is a key part of ensuring low downtime and high productivity. Dock seals, overhead doors, and dock levelers wear out over time and repeated usage, which makes regular service from a professional one of the most important things you can have on your maintenance checklist.

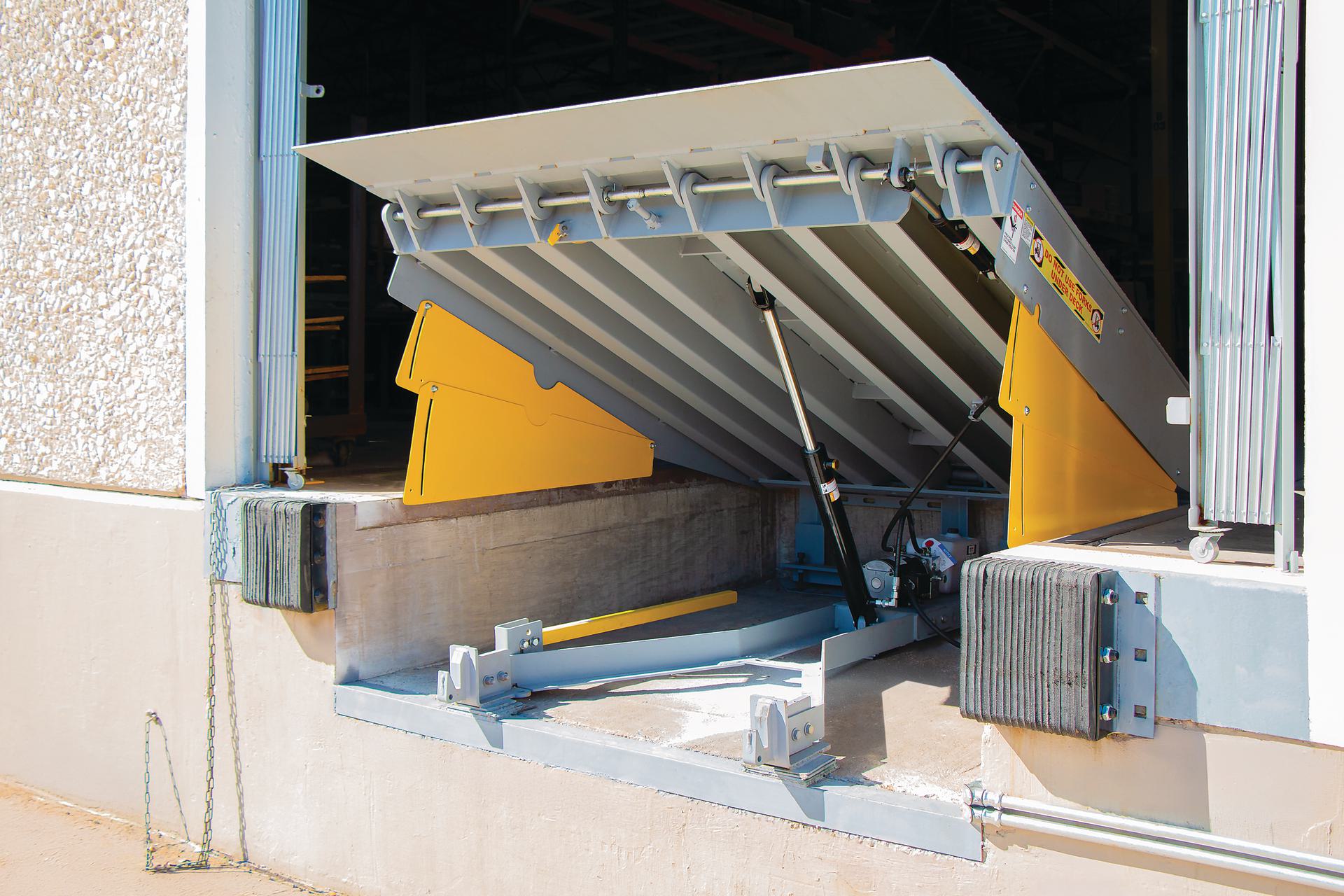

Dock Levelers

Dock levelers form the essential bridge between trailers and your loading dock, allowing for smooth, safe loading and unloading while also accommodating a greater range of trailer sizes. Keeping an eye out for damage or mechanical problems helps avoid costly disruptions and repairs, maintaining crucial uptime for your operations.

Cracks or Visible Damage in the Structure

During your inspection of your dock level or pit leveler, look for cracks, stress fractures, or compromised weld points. Even minor surface damage can worsen over time and affect stability, but addressing small issues early on can prevent larger, more expensive failures later on. Visible cracking or deformation may indicate a deeper structural issue, requiring replacement rather than repair.

Platform Damage

A dock leveler or pit leveler that’s brand new should have a surface that’s nice and smooth. There should be no grooves, dents, or uneven spots. Any surface damage of that nature is an indicator that the material has started to stretch and break down and should be addressed immediately.

Damage to the surface of your dock leveler is a hazard to your operations in a few different ways. It can reduce productivity as workers need to maneuver around the damaged areas and can even lead to damage to other equipment such as forklifts, pallet jacks, or carts. It also represents a safety hazard as worn equipment can break without warning, causing injuries and impacting operation.

Mechanical Problems

If your dock leveler struggles to raise or lower, moves unevenly, or makes unusual noises, mechanical issues may be to blame. These problems can slow down operations and create unsafe working conditions for your employees. Fortunately, most mechanical issues can be quickly corrected by a qualified technician before they lead to major downtime or injuries.

Sectional Dock Doors

Sectional dock doors are built for durability but still experience significant wear over repeated cycles. Issues with tracks, cables, or operating speed can develop gradually, impacting performance and efficiency.

Damage to Tracks and Cables

Subjected to heavy daily use, cables and tracks are prone to wear and misalignment. Frayed cables or bent tracks can cause unsafe operation and should be repaired immediately. Professional service ensures these components are replaced or realigned correctly to keep your sectional dock doors working as intended.

Your Door is Too Slow

If your sectional loading dock door is sluggish or moving slower than usual, a motor, spring, or balance could be at fault and could slow down more than your operations. By leaving your sectional door open for longer than necessary, you can also slow down your efforts for a greener and safer facility. With air infiltrations and prolonged exposure to the elements, not only will your slow door put undue strain on your HVAC system and increase your energy bills, but the water, snow, or debris can cause unsafe working conditions and put your employees at risk. A slow-moving door should be inspected promptly by a professional for a complete diagnostic and fast remediation of the issue.

Dock Seals and Shelters

Dock seals and shelters create a protective barrier between your facility and parked trailers, improving safety and energy efficiency. Though they are built to withstand heavy use, dock seals and shelters inevitably degrade over time. Signs of damage include gaps around trailers, as well as obvious wear on the seals themselves. Damage and gaps are vulnerabilities in your seals, allowing the outside environment to intrude on your loading dock. This can be in the form of non-conditioned air, rain, ice, or even pests. You’ll lose energy efficiency and reduce safety in these key areas.

Light Gaps Around Parked Trailers

The next time you have a trailer parked at your loading dock, take a second to inspect the dock seal from the inside. It should be completely airtight, with no visible light shining in around the trailer. A good dock seal or shelter will provide a tight, effective, and dark seal around the sides and along the top. If your seal has any gaps or damage that are affecting its ability to perform, you’ll notice it in the form of light shining through.

Noticeable Wear and Tear

Dock seals and shelters rack up a noticeable amount of wear and tear over time thanks to their continuous interaction with heavy semi-trailers. The repeated process of trucks backing into the seal can lead to tears, punctures, sagging materials, and exposed foam over time. Shelters are also susceptible to damage from trailers if they end up backing into the dock off-centre. You can make a quick visual inspection of you dock seal or shelter to find any obvious damage.

Benefits of Regular Service

Scheduling routine professional service is one of the smartest investments you can make for your loading dock. Heavy daily use causes wear that can go unnoticed until it disrupts operations, but regular maintenance identifies small problems before they become major failures, saving you time, money, and stress.

A professional from Creative Door Services will perform a thorough inspection during off hours to avoid disrupting your work. The inspection will reveal any problem areas that require attention, avoiding breakdowns, enhancing safety, and ensuring that you can maintain productive uptime.

Call Creative Door Services for Professional Dock Equipment Repair Service

Creative Door Services is your one-stop shop for all the professional dock equipment servicing you need. Our skilled technicians have years of experience in commercial environments, so they know exactly what kind of damage to look for. Additionally, we maintain one of the largest inventories of parts in Western Canada that we can use to quickly and easily maintain your equipment.

When you need a service call, reach out to Creative Door Services. You can find us in Kelowna, British Columbia; Vancouver, British Columbia; Calgary, Alberta; Edmonton, Alberta; Fort McMurray, Alberta; Regina, Saskatchewan; Saskatoon, Saskatchewan; and Winnipeg, Manitoba to request a quote.